Advantages of Membrane Keypad Design for Medical Electronics

Technology has improved a lot and

bounds in a small period. In this technologically advanced era, there are

amazing innovative inventions found, such as Membrane keypads and switches. Membrane

keypads act as an aesthetic user that interferes with the hardware

and software control system. Everyone uses these keypads in day today's lives,

microwaves operate, dishwashers, or washing machines, through membrane keypads.

This technology may look smaller and weightless but is the better usage it

generates. Membrane keypads are the best examples of advanced modern

technology. And it brings easy solutions for all the present-day problems.

Membrane keypads and switches are

designed very well suited for medical electronics. It is more apt for handheld

medical equipment and the portable device. Membrane keypads and switches are

lightweight, durable, low profile, and are easy to clean. A wide variety of

membrane keypads and switches are available in the market according to the user

needs. Membrane keypads are not only designed for medical electronics, but also

a choice of interface for many other products, including industrial controls,

automotive controls, toys, and games.

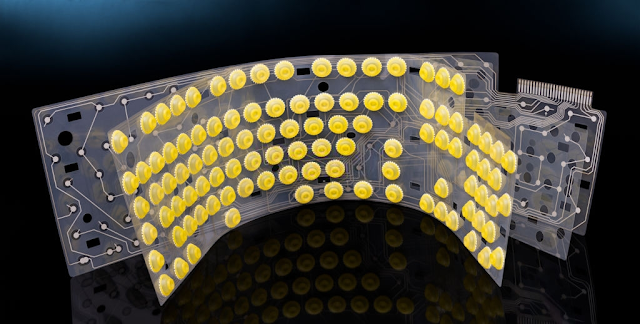

What are Membrane keypads and Switches?

Membrane keypads or switches are

non-separate and a whole pressure design pads. They have only outlines and

symbols printed on a stretchy flat surface. Membrane keypads are functioning

with electrical contact between underneath the circuit and keypad surface when

the keypads are pressed. They are used in many different industries, including

white goods, medical, electronics, marine, and security.

Design: Membrane keypads and switches designed to keep them free of

grime and dirt. As mentioned before, it is a fully sealed surface that makes

cleaning and maintenance easy. There is no clot of dirt or grime, so the

circuit function smoothly and making them more durable. Adaptive designs are

available for different needs of customers, and some designs are waterproof.

Durability: According to the budget, the material used to make

these membranes differs. There are two different materials used for production:

Polycarbonate (Lexan) and Polyester (PET). Polyester is a bit expensive, and

Polycarbonate is more of an aesthetic choice. While using solvent-based

chemicals, it won’t be effective in cost-effective Polycarbonate. The fully

sealed membrane keypad and switches offer easy cleaning and durability.

Easy to clean and maintain: Membrane

keypads and switches are easy to clean and maintain. They are

exposed to all kinds of dirt and grime, and the switches set in the socket

where they installed. Moreover, membrane keypads and switches sealed from all

sides and are much smoother.

Cost-effective and Easy Repairs: Membrane keypads are

cost-effective and resistant to liquids and grimes. When compared to other

keyboards, membrane keypads are much easier to repair. If any damage occurs,

you can easily remove the overlaying membrane, repair the problems in the

circuit, and place them back to make it fully functioning again. This easy

repairing method makes it more flexible in many industries.

Enhanced Shielding: Membrane keypads panel offers shielding and protection against

electrostatic discharge. Basically, protection can adopt without negotiating

the performance of the switch panels. Membrane keypads and switches have the

advantages of offering better shielding to the product. And it is designed to

be waterproof, which can protect machinery from any liquid mishap. Using

waterproof material for domestic appliances membrane can protect and save the

owner from spending more cash for repairing with any liquid mishap.

Adaptability and Flexibility: The material used for

manufacturing makes printing digitally. It gives accurate and crisp graphics

which integrated with backlit membrane keypads and switches or with LED. Membrane

keypads and switches are flexible in size and easily fit in any

machinery or product for use.

Comments

Post a Comment